Special requirement examples

Type of sockets and applications

MEMS Sensor Sockets

- Gyro sensor sockets, Acceleration sensor sockets

- Pressure and atmosphere pressure sensor sockets

- Temperature and humidity sensor sockets

- Microphone sensor sockets

Integrated circuit device sockets

Wondering what package sizes are offered for crystal devices?

Crystal Device Sockets

MiS solutions

Standard product line offers 25×25, 25×22, 14×9, 9×7, 7×5, 5×3.2, 3.2×2.5, 2.5×2.0, 2.0×1.6, 1.6×1.2, 1.2×1.0, 1.0×0.8, 0.8×0.6 mm packages, which covers most of, if not all, package dimensions and pad configurations available in the market.(Over 1,100 package types)

Customized test sockets are also available for your unique package dimensions and requirements. Please contact us.

High Frequency Crystal Device Sockets

Crystal Device Sockets

MiS solutions

MiS technologies has offered sockets that utilize low profile and short probe contact pins to keep the signal path short.

Highly-Efficient Thermal Dissipation Test Sockets

Crystal Device Sockets

MiS solutions

Thermal dissipating designs allow for thermally stable measurements with heat sinks, temperature dissipating probe contacts, and thermal conductive film.

These technologies can solve self-heating of devices under test.

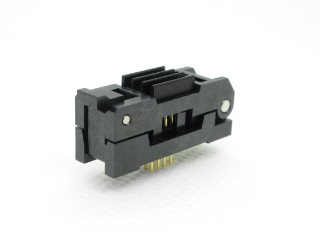

Contacting side pads of crystal devices

Crystal Device Sockets

MiS solutions

Many crystal devices have pads not only the bottom but also on the sides of packages. MiS Technologies offers open-top style sockets that utilizes stamping contacts to contact to the side pads.

This solution help for stable measurements.

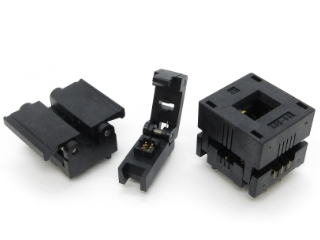

Socket type (Open top, clamshell, butterfly) selections

Crystal Device Sockets

MiS solutions

MiS Technologies evaluate your needs to select best suitable socket solutions. We offer open-top, clamshell and butterfly types. Open-top and butterfly type are best suited for automated pick and place production environment while clamshell type is a good fit for manual testing for development qualification tests.

We will select a solution from standard off-the-shelf design socket and customized design sockets. Please contact us.

Low-cost test socket solutions

Gyro sensor sockets, Acceleration sensor sockets

MiS solutions

Semi-customized test sockets can be offered using probe contact pins and stamping contact pins to satisfy low budget needs.

Gyro sensors are sensitive to relative position of the device to the socket, physical stress, and other environmental external factors on the packages. This is one of MiS Technologies’ top product lines. Our gyro sensor sockets are used by top tier OEMs. Please contact us.

Low-cost customized sockets

Pressure and atmosphere pressure sensor sockets

MiS solutions

One of our strengths is customization and support small quantities for various packages.

For example, pressure sensors come in different package shapes and often pressure-sensing nozzle are in different shapes and sizes. MiS Technologies stocks variety of customized mold tooling to combine them to offer initial-low-cost solutions. Pressure sensor sockets use probe pin contacts. The contact pressure on the packages can be controlled by the spring in the probe pin contacts.

Hygroscopic property of mold resin used for sockets

Temperature and humidity sensor sockets

MiS solutions

HAST test typically sets temperature higher than 100C and relative humidity near 100%.

Since high hygroscopic mold resin cannot be used for accurate measurement, MiS socket uses very low hygroscopic property mold resin for socket body and the cover, which allows for stringent environmental tests.

Quick turn-around test sockets for R&D ambient temperature qualification tests

Microphone sensor sockets

MiS solutions

For ambient temperature R&D device functionality evaluation, MiS offers 3D printing sockets which allows for quick turn-around production. 3D printing test socket is one of MiS’s strengths.

3D printing socket option is significantly cost effective than machining sockets (approximately 1/10X) Customers are satisfied with quick turn-around 3D printing sockets for ambient testing. Top-side-down insertion method also helps to decrease the number of parts used, which in turn reduce the cost of the sockets.

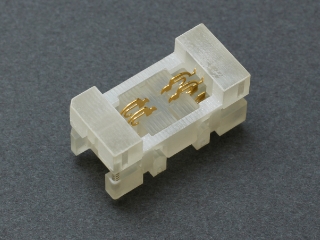

Looking for MLCC sockets for miniature devices

MLCC sockets

MiS solutions

MiS is the only supplier for MLCC socket (Multi-Layer Ceramic Capacitor) in the world. Many customers are interested in the socket solution.

We design and develop miniature test sockets for customers’ requirements of testing small devices such as resistors and MEMS devices.

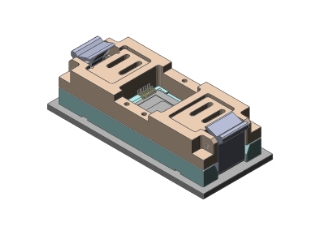

Inspecting bare chips in biased condition

Sockets for bare chips

MiS solutions

Our customer contacted us through the website for a test socket to inspect bare chips while being biased.

We designed a socket with a large opening on the top of the socket which allows the customer to inspect die surface by microscope while biasing it. The socket design consists of separated cover and body for better cooling and easy insertions.